Asahi Rubber INC.

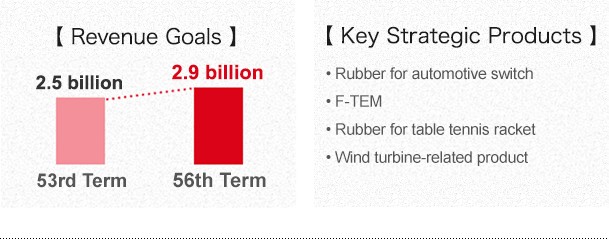

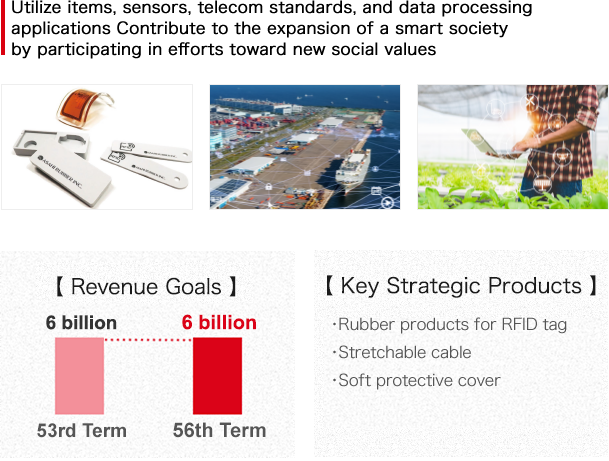

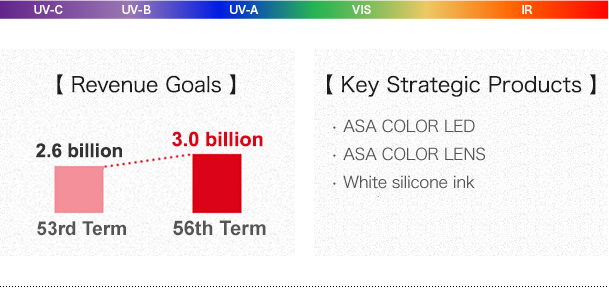

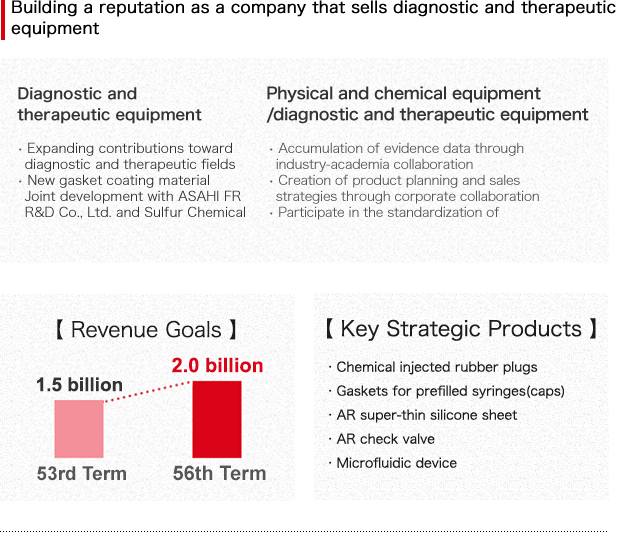

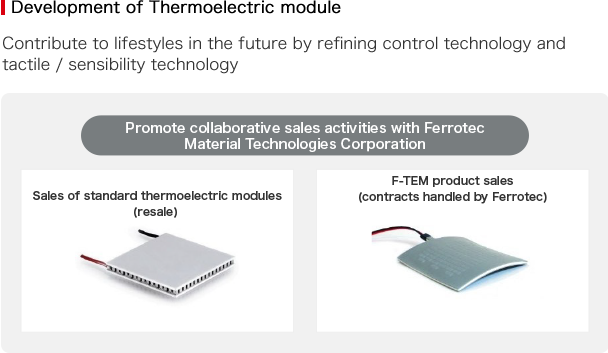

We will divide our priority business fields into four areas and organize the roles of core technologies and factories that will make each product line grow, then advance initiatives to make the most of the production environment we have established so far.

O&M※Advancing toward commercialization

※O&M:Maintenance of facilities and equipment following completion of construction