Asahi Rubber INC.

Home > Development & Technology Information > Technology information > Material denaturalization technology

Soft materials including rubber can be given desired functions by mixing and compounding additives with the raw material. In addition, such functions can be further reinforced by molding on the Nano / molecular level. Such technology is called material denaturalization technology.

Nano / molecular level vulcanization composition Electromagnetic wave control body

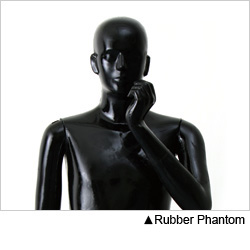

"Rubber Phantom" with high potential

With the emergence of the ubiquitous society, all the electronic devices essential for our daily life emit electromagnetic waves. The "Rubber Phantom” is useful for measuring how such electromagnetic waves are propagated when people are nearby. This product has been adopted by such companies as NTT DoCoMo Inc., Panasonic Corporation, and Mitsubishi Electric Corporation. In addition, paying attention to that fact that human body transmits weak electric waves, we have started a number of experiments demonstrating use of intra-body communication for data communication. This technology is on the verge of commercialization and the "Rubber Phantom" is also used in this field.

Characteristics attracting worldwide attention

"Rubber Phantom" is made from silicone rubber together with fiber-reinforced plastic to support its frame. It controls electrical characteristics by combining conductive substances including carbon nanotube. As silicone rubber has high stability, electrical characteristics will not change, depending on temperature or humidity in the environment when it is used. In addition, "Rubber Phantom" is more reasonable and less likely to deteriorate compared to other measurement devices made from liquid, agar, ceramics, and resins. Thus, it has been attracting worldwide attention.

"Rubber Phantom" is made from silicone rubber together with fiber-reinforced plastic to support its frame. It controls electrical characteristics by combining conductive substances including carbon nanotube. As silicone rubber has high stability, electrical characteristics will not change, depending on temperature or humidity in the environment when it is used. In addition, "Rubber Phantom" is more reasonable and less likely to deteriorate compared to other measurement devices made from liquid, agar, ceramics, and resins. Thus, it has been attracting worldwide attention.

Reproducing the same electrical characteristics as the human body in a reliable manner, this whole human body phantom can be manufactured in various postures including standing upright and sitting down which were never available before. Body parts such as hand or head only can also be supplied. In addition, sensors and chips for measurement can be built into the device in the manufacturing process. Patents are pending and the trademark has been registered.

Nano / molecular level vulcanization blend "Saporous"

Foaming technology which doesn’t use chemical foaming agent

When it comes to foaming, styrene foam used as wrapping and cushioning material is widely known. This foam is light and highly shock absorbent, but it is generally made from gas foaming using chemical foaming agent. "Saporous" is a continuous foaming technology which doesn’t use chemical foaming agent, and it doesn’t cause allergy even when used close to human skin. Not only is it light and shock-absorbent, but also it is breathable and highly water-resistant. It is anticipated that "Saporous" will be applied to various fields including long-term care and sports tools.

When it comes to foaming, styrene foam used as wrapping and cushioning material is widely known. This foam is light and highly shock absorbent, but it is generally made from gas foaming using chemical foaming agent. "Saporous" is a continuous foaming technology which doesn’t use chemical foaming agent, and it doesn’t cause allergy even when used close to human skin. Not only is it light and shock-absorbent, but also it is breathable and highly water-resistant. It is anticipated that "Saporous" will be applied to various fields including long-term care and sports tools.