Asahi Rubber INC.

Home > Development & Technology Information > Technology information > Color / light control technology

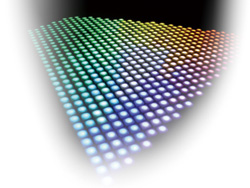

This technology can not only make various colors, precisely control color tone, but also control light by providing transparent silicone resin with optical properties such as light focusing / diffusing. The product made with this technology was given Asahi Color brand and its trademark was registered in both Japan and the United States.

To ASA COLOR LED product page To ASA COLOR LENS product page

To ASA COLOR LED product page To ASA COLOR LENS product page

Color match / tone control ASA COLOR LED

The combination between LED’s environmental performance and our core technology has lead to the development of ASA COLOR LED

With environmental issues getting worldwide attentions and requiring urgent solution, in-vehicle interior illumination has started to shift to LED from electric bulbs. As LED is characterized by longer lifetime, low energy consumption and does not contain environmentally hazardous substance, it is considered to be the next generation light source, one of the solutions to environmental issues. In addition to conventional colors such as red, green, orange, blue LED was developed. Thus the three primary colors of light have become available for LED. Moreover, the development of white LED that stably produces white light has significantly promoted the use of LED.

With environmental issues getting worldwide attentions and requiring urgent solution, in-vehicle interior illumination has started to shift to LED from electric bulbs. As LED is characterized by longer lifetime, low energy consumption and does not contain environmentally hazardous substance, it is considered to be the next generation light source, one of the solutions to environmental issues. In addition to conventional colors such as red, green, orange, blue LED was developed. Thus the three primary colors of light have become available for LED. Moreover, the development of white LED that stably produces white light has significantly promoted the use of LED.

As we had started research into color and light variations using LED as light source to quickly respond to the market development, we paid attentions to blue LED with shorter wavelength, which makes it easier to control light. Accordingly, we entered into the new technological field where we can use LED technology, coupled with our technology to make colors and light, which had long been developed for ASA COLOR LAMP CAP, a color cap to apply on electric bulbs

Thoroughly respond to customer needs in detail

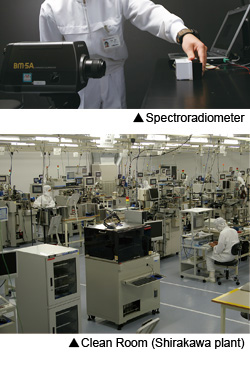

Technically, it is extremely difficult to make our unique color consistency only with light source and supply them in a large volume in a stable manner. LED is a case in point, too. For example, some colors such as a kind of white color gradated more towards warm white like electric bulbs rather than pure white, or white color variation with subtle orange are difficult to make only with LED. Our technology for silicone rubber composition based on our clear understanding of phosphor's characteristics along with the technology to make color consistency by applying cap onto individual LED according to their characteristics through measurement and classification of deviations in producing light are our strength and the most important distinctive feature of ASA COLOR LED. Not only sales representatives but also engineers and researchers of ASAHI FR R&D Co.,Ltd., a subsidiary of Asahi Rubber will directly meet with our customers to listen to their needs and satisfy their expectations by effectively using color luminance meter and spectroradiometer.

Technically, it is extremely difficult to make our unique color consistency only with light source and supply them in a large volume in a stable manner. LED is a case in point, too. For example, some colors such as a kind of white color gradated more towards warm white like electric bulbs rather than pure white, or white color variation with subtle orange are difficult to make only with LED. Our technology for silicone rubber composition based on our clear understanding of phosphor's characteristics along with the technology to make color consistency by applying cap onto individual LED according to their characteristics through measurement and classification of deviations in producing light are our strength and the most important distinctive feature of ASA COLOR LED. Not only sales representatives but also engineers and researchers of ASAHI FR R&D Co.,Ltd., a subsidiary of Asahi Rubber will directly meet with our customers to listen to their needs and satisfy their expectations by effectively using color luminance meter and spectroradiometer.

Optical engineering ASA LENS

ASA LENS has strong resistance to heat and ultraviolet radiation. It is light with optical properties.

As we mainly deal with products made from silicone rubber, we paid attentions to transparent silicone materials. They are light and have strong resistance to heat and ultraviolet radiation. Taking advantage of such characteristics as well as the function of lens such as light focusing and diffusing, we successfully combined the materials with LED. This new technology has been used for power LED, or automotive headlight for ecologically-friendly cars, in addition to flash of mobile phone cameras and infrared light sensors, thus paving the way for new applications.

As we mainly deal with products made from silicone rubber, we paid attentions to transparent silicone materials. They are light and have strong resistance to heat and ultraviolet radiation. Taking advantage of such characteristics as well as the function of lens such as light focusing and diffusing, we successfully combined the materials with LED. This new technology has been used for power LED, or automotive headlight for ecologically-friendly cars, in addition to flash of mobile phone cameras and infrared light sensors, thus paving the way for new applications.

Respond to customer needs by improving production system including state-of-the-art technology and automation

Shirakawa Plant producing ASA COLOR LED, LENS, and others is equipped with environmental testing machines to measure temperature and humidity, such as spectroradiometer and color luminance meter. The production space is clean room controlled to keep a certain degree of temperature and humidity, with the conductive floor eliminating static electricity. In the liquid cleaning process to get rid of low molecular substance contained in silicone rubber, liquid is recycled through distillation and reproduction so as not to discharge waste liquid from the plant. The production lines beginning with testing and classification of material attributes are full of originally designed automated equipment. These facilities supported by our production technology and testing system always gain confidence of visitors to our plant.

Shirakawa Plant producing ASA COLOR LED, LENS, and others is equipped with environmental testing machines to measure temperature and humidity, such as spectroradiometer and color luminance meter. The production space is clean room controlled to keep a certain degree of temperature and humidity, with the conductive floor eliminating static electricity. In the liquid cleaning process to get rid of low molecular substance contained in silicone rubber, liquid is recycled through distillation and reproduction so as not to discharge waste liquid from the plant. The production lines beginning with testing and classification of material attributes are full of originally designed automated equipment. These facilities supported by our production technology and testing system always gain confidence of visitors to our plant.

To ASA CPLOR LENS production page