R&D

We develop products based on three core technologies. The following is an introduction to our specific development structure, details of core technologies, and initiatives related to product development.

The Strength of ASAHI RUBBER

01Flexible and responsive

With many years of experience in OEM products, we can flexibly respond to the specifications demanded by our customers.

By actively incorporating new elements beyond rubber, we are advancing the transformation from OEM to ODM, offering a wide range of products across various sectors such as automotive, medical, and communications.

02Reliable technical capability

Asahi Rubber proposes products from all angles of QCDSE based on our three core technologies. The technologies we have accumulated through our involvement in a wide range of product development have a broad base, so we are actively involved in planning, proposing, and collaborating on products that are not limited to rubber.

03Sincerity

Even if it was difficult to solve a problem with our past experience, we have continued to explore ways to solve it and take on new challenges. As a result, we have received the words, “If it's Asahi Rubber, they can do something about it,” and Asahi Rubber has grown significantly. We will continue to be close to our customers and sincerely address their problems.

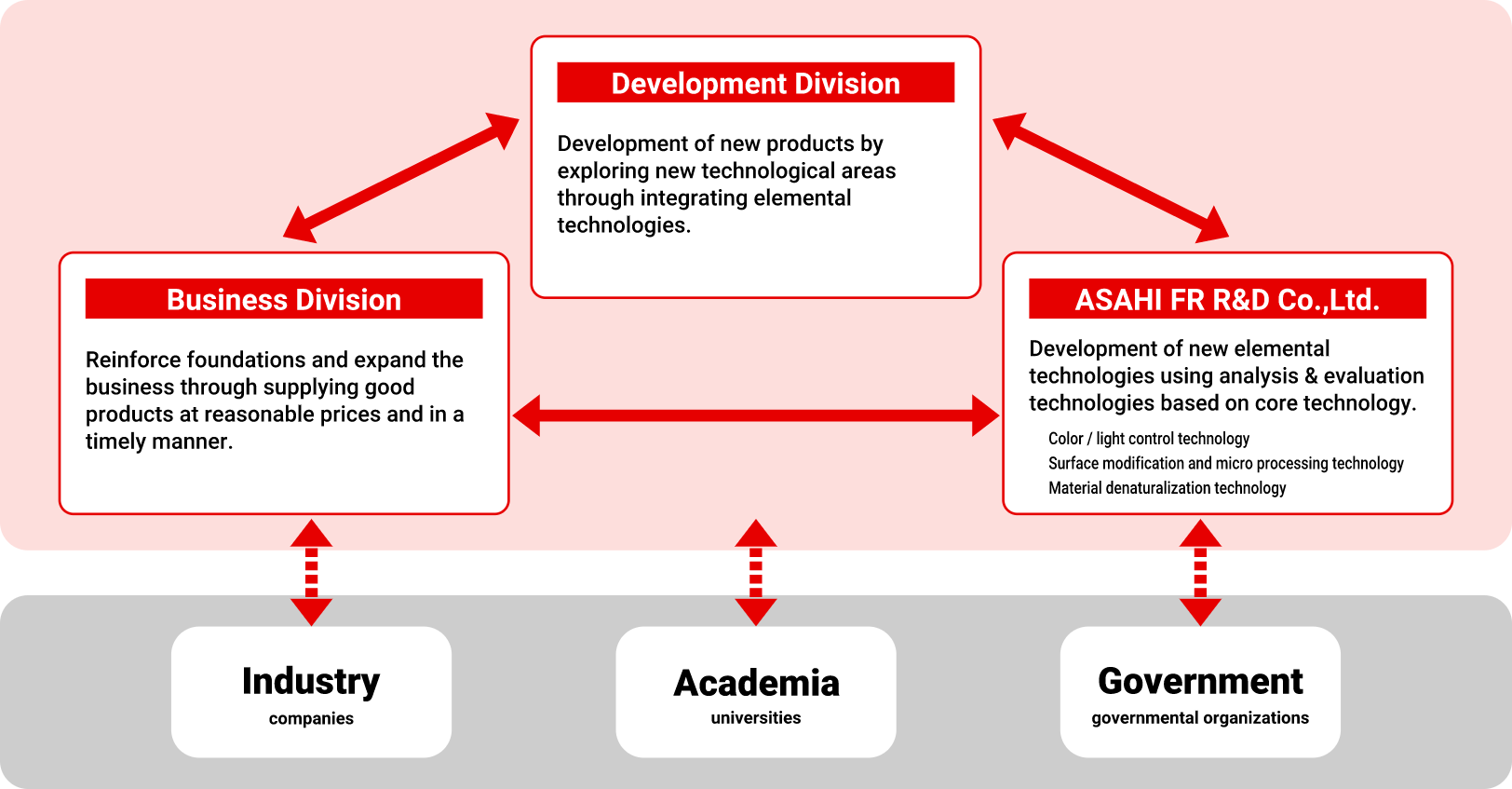

Development System

We are strengthening cooperation between technology, sales, and research to create a development system that will enable us to demonstrate our comprehensive strengths as a company.For the purpose of creating new business, new products and reinforcing technology platform, "Strategic development themes" are being driven forward by internal and external technology merge as well as state of the art technology incorporation.

Doctor of Engineering

Asahi Rubber Inc, has been focused on R&D ever since its establishment and has introduced a lot of new products into the market. As a part of the activities, we support what we call coordination between industry and academia, i.e. cooperation with universities. We regard the activities as an important initiative to promote the development of new products. As a matter of fact, in joint research with Hokkaido University, we have commercially developed "Rubber Phantom", a whole human body phantom for measuring electromagnetic waves, and we have also designed "Saporous" welfare and long-term care goods using sanitary, shock-absorbent foam with Nihon University. In addition, we encourage executives and associates of subsidiaries to take Ph. D. courses for working people and to obtain Doctor's degrees in university laboratories.

ASAHI RUBBER INC. President

ASAHI FR R&D Co.,Ltd. President

Doctor of Engineering Yoichiro Watanabe

Research theme

“Research info manufacturing polymer porous bodies”

ASAHI FR R&D Co.,Ltd.

Doctor of Engineering Kazuki Gyoda

Research theme

“Fluid adhesion between titanium and epoxy resin using a molecular adhesive”

ASAHI FR R&D Co.,Ltd.

Doctor of Engineering Nobuyoshi Watanabe

Research theme

“Study on thermal conductive silicone rubber composites”

ASAHI RUBBER INC.

Doctor of Engineering Masashi Nemoto

Research theme

“Research on Fluid Molecular Bonding of Aluminum Substrates and Elastomers”

ASAHI RUBBER INC.

Doctor of Engineering Takashi Kanahira

Research theme

“Research on industrial materials marketing for secondary subcontractors”

ASAHI FR R&D Co.,Ltd.

Doctor of Engineering Sho Mihara

Research theme

“Development of Highly Stretchable Polydimethylsiloxane Nanosheets and Their Application to Skin-Contact Devices.”

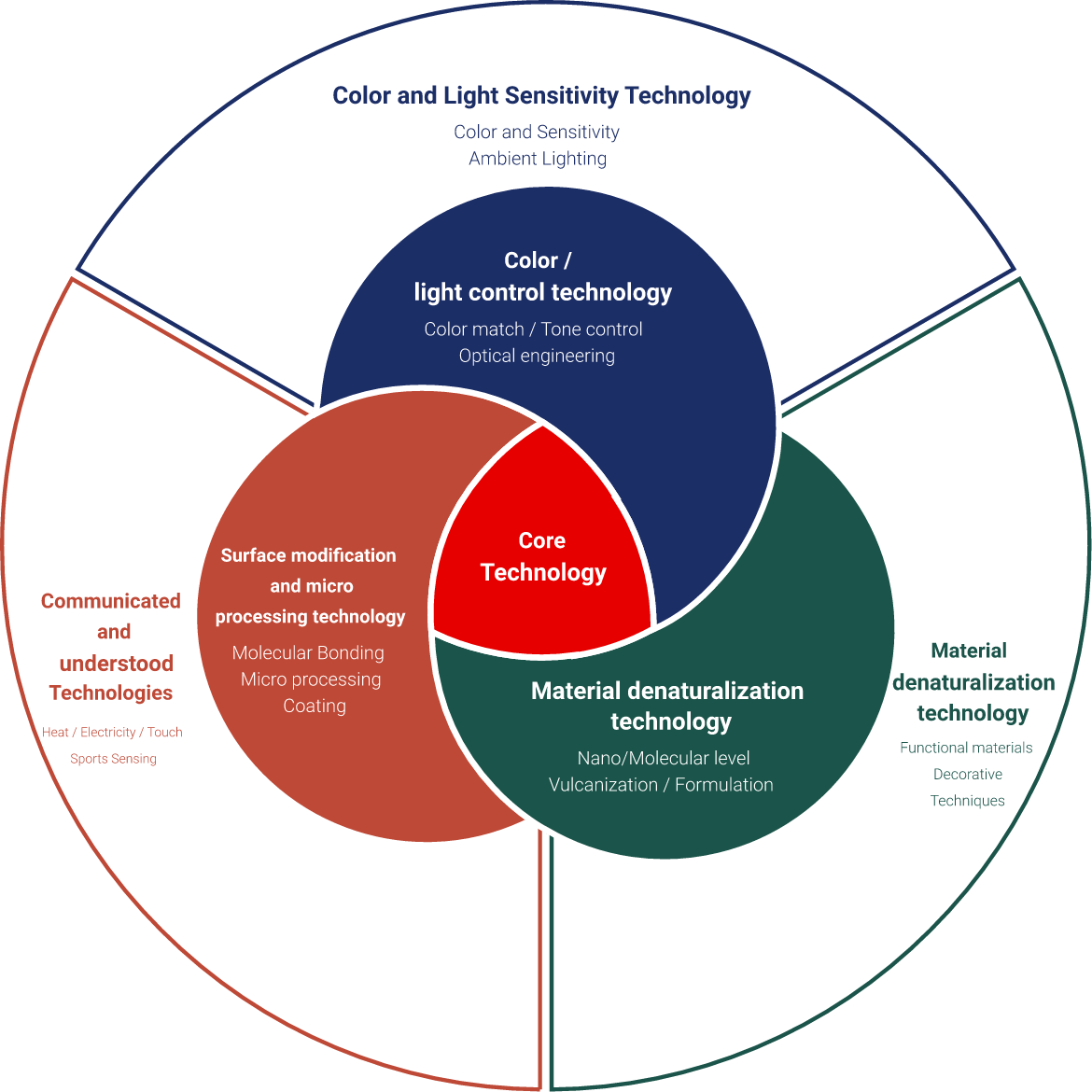

Technology Information

Live up to customers' expectations with high quality and economic efficiency

ASAHI RUBBER INC. aims to live up to customers' expectations by developing essential parts for products which help to solve environmental issues including human health problems and innovative products for creating new green markets, adding the keywords for growth of “mastery and sensitivity”, based on our three core technologies of: "color / light control", "surface modification and micro processing", and "material denaturalization", each a source of our unique competitiveness.

Core Technology “Mastery & Sensitivity"

Color / light control technology

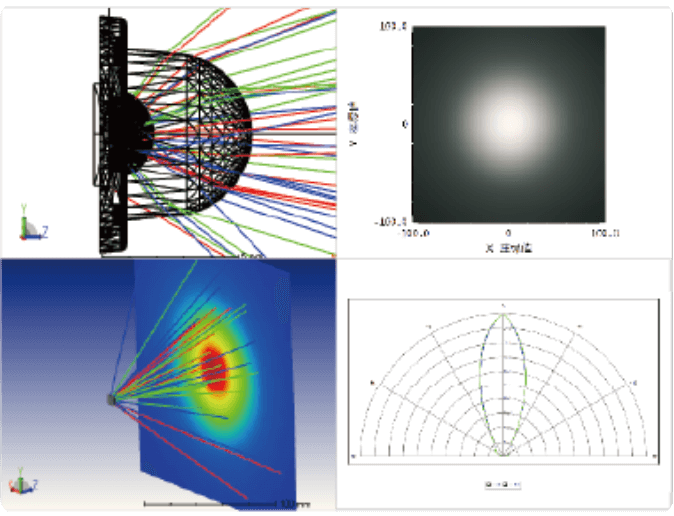

This technology can not only precisely control color tone and make various colors, but it can also control light by providing transparent silicone resin with optical functions such as light focusing / diffusing. Products made with this technology have been given the ASA COLOR brand name, which has become a registered trademark in both Japan and the United States.

brand

brand

brand was created to globally market products applied to optical devices by using unique composition and color tone technology for silicone materials.

brand was created to globally market products applied to optical devices by using unique composition and color tone technology for silicone materials.

(ASA COLOR is a trademark of ASAHI RUBBER INC.)

More than 10,000 color variations are available by eliminating deviation in producing light of LED, which is greatly expected as the next generation illumination.

This has been mainly used as a light source for in-vehicle illumination.

This lens is made from light-permeable silicone resins, and less degrading over time compared to other resin lens,and has optical properties including light focusing / diffusing.

Color match / tone control ASA COLOR LED

The combination between LED’s environmental performance and our core technology has lead to the development of ASA COLOR LED

With environmental issues getting worldwide attentions and requiring urgent solution, in-vehicle interior illumination has started to shift to LED from electric bulbs. As LED is characterized by longer lifetime, low energy consumption and does not contain environmentally hazardous substance, it is considered to be the next generation light source, one of the solutions to environmental issues. In addition to conventional colors such as red, green, orange, blue LED was developed. Thus the three primary colors of light have become available for LED. Moreover, the development of white LED that stably produces white light has significantly promoted the use of LED.

As we had started research into color and light variations using LED as light source to quickly respond to the market development, we paid attentions to blue LED with shorter wavelength, which makes it easier to control light. Accordingly, we entered into the new technological field where we can use LED technology, coupled with our technology to make colors and light, which had long been developed for ASA COLOR LAMP CAP, a color cap to apply on electric bulbs.

Thoroughly respond to customer needs in detail

Technically, it is extremely difficult to make our unique color consistency only with light source and supply them in a large volume in a stable manner. LED is a case in point, too. For example, some colors such as a kind of white color gradated more towards warm white like electric bulbs rather than pure white, or white color variation with subtle orange are difficult to make only with LED. Our technology for silicone rubber composition based on our clear understanding of phosphor's characteristics along with the technology to make color consistency by applying cap onto individual LED according to their characteristics through measurement and classification of deviations in producing light are our strength and the most important distinctive feature of ASA COLOR LED. Not only sales representatives but also engineers and researchers of ASAHI FR R&D Co.,Ltd., a subsidiary of Asahi Rubber will directly meet with our customers to listen to their needs and satisfy their expectations by effectively using color luminance meter and spectroradiometer.

Optical engineering ASA LENS

ASA LENS has strong resistance to heat and ultraviolet radiation. It is light with optical properties

As we mainly deal with products made from silicone rubber, we paid attentions to transparent silicone materials. They are light and have strong resistance to heat and ultraviolet radiation. Taking advantage of such characteristics as well as the function of lens such as light focusing and diffusing, we successfully combined the materials with LED. This new technology has been used for power LED, or automotive headlight for ecologically-friendly cars, in addition to flash of mobile phone cameras and infrared light sensors, thus paving the way for new applications.

Respond to customer needs by improving production system including state-of-the-art technology and automation

Shirakawa Plant producing ASA COLOR LED, LENS, and others is equipped with environmental testing machines to measure temperature and humidity, such as spectroradiometer and color luminance meter. The production space is clean room controlled to keep a certain degree of temperature and humidity, with the conductive floor eliminating static electricity. In the liquid cleaning process to get rid of low molecular substances contained in silicone rubber, liquid is recycled through distillation and reproduction so as not to discharge waste liquid from the plant. The production lines beginning with testing and classification of material attributes are full of originally designed automated equipment. These facilities supported by our production technology and testing system always gain the confidence of visitors to our plant.

Material denaturalization technology

Soft materials including rubber can be given desired functions by mixing and compounding additives with the raw material. In addition, such functions can be further reinforced by molding on the Nano / molecular level. Such technology is called material denaturalization technology.

Nano / molecular level vulcanization composition Electromagnetic wave control body

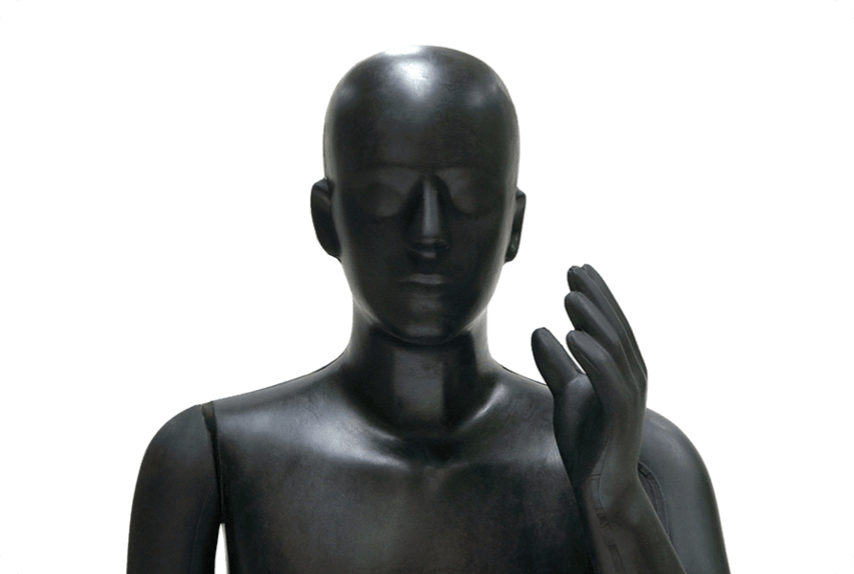

"Rubber Phantom" with high potential

With the emergence of the ubiquitous society, all the electronic devices essential for our daily life emit electromagnetic waves. The "Rubber Phantom” is useful for measuring how such electromagnetic waves are propagated when people are nearby. This product has been adopted by such companies as NTT DoCoMo Inc., Panasonic Corporation, and Mitsubishi Electric Corporation. In addition, paying attention to that fact that human body transmits weak electric waves, we have started a number of experiments demonstrating use of intra-body communication for data communication. This technology is on the verge of commercialization and the "Rubber Phantom" is also used in this field.

Characteristics attracting worldwide attention

"Rubber Phantom" is made from silicone rubber together with fiber-reinforced plastic to support its frame. It controls electrical characteristics by combining conductive substances including carbon nanotube. As silicone rubber has high stability, electrical characteristics will not change, depending on temperature or humidity in the environment when it is used. In addition, "Rubber Phantom" is more reasonable and less likely to deteriorate compared to other measurement devices made from liquid, agar, ceramics, and resins. Thus, it has been attracting worldwide attention.

Reproducing the same electrical characteristics as the human body in a reliable manner, this whole human body phantom can be manufactured in various postures including standing upright and sitting down which were never available before. Body parts such as hand or head only can also be supplied. In addition, sensors and chips for measurement can be built into the device in the manufacturing process. Patents are pending and the trademark has been registered.

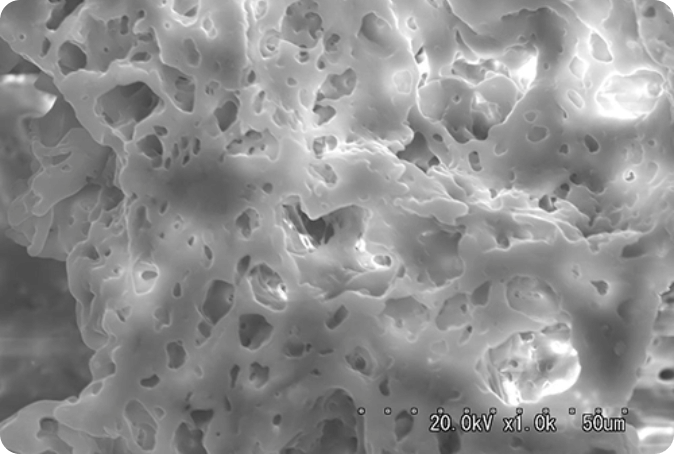

Nano / molecular level vulcanization blend "Saporous"

Foaming technology which doesn’t use chemical foaming agent

When it comes to foaming, styrene foam used as wrapping and cushioning material is widely known. This foam is light and highly shock absorbent, but it is generally made from gas foaming using chemical foaming agent. "Saporous" is a continuous foaming technology which doesn’t use chemical foaming agent, and it doesn’t cause allergy even when used close to human skin. Not only is it light and shock-absorbent, but also it is breathable and highly water-resistant. It is anticipated that "Saporous" will be applied to various fields including long-term care and sports tools.

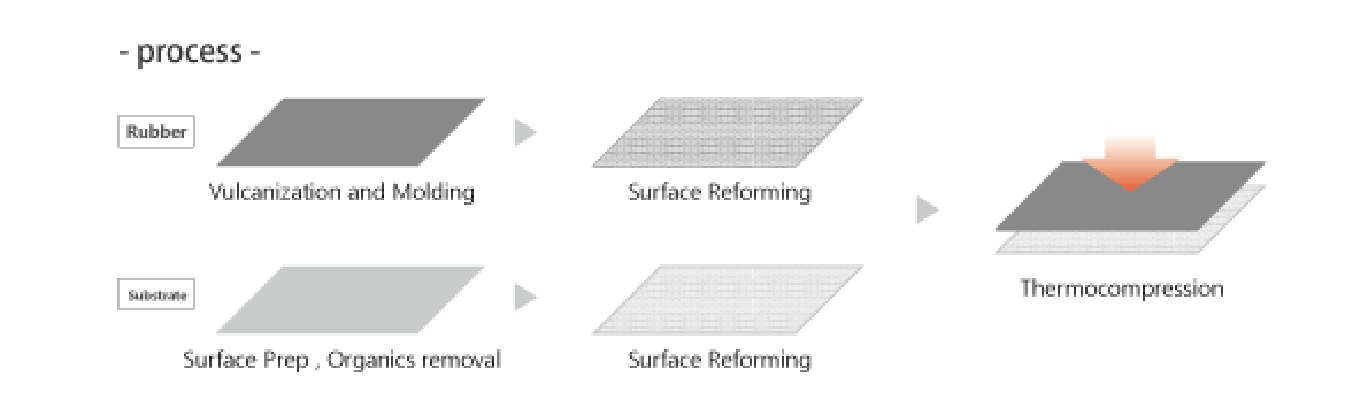

Surface modification and micro processing technology

This technology enables attachment by modifying material surface as well as additional functions through micro processing. While material denaturalization technology adds functions to materials internally, this technology adds functions externally.

Solvent-less attachment IC tag

New soft IC tag, which is compact and strong to bending, water, and heat

IC tag is a small-sized information chip. This technology is used for identification and has been studied and evolved as alternative technology to barcode. For example, it is applied to the automated book circulation system for libraries managing a large volume of books, transportation equipment used for logistics, and building security devices like enter/leave management. Thus, this technology has various applications.

By using "solvent-less attachment," one of our surface modification technology to cover IC chip or the antenna part with rubber materials, we developed soft compact IC tag which is strong to bending, water, and heat.

Micro processing technology: Relief valves for secondary battery and fuel battery

We provide parts inevitable for environmental technology such as secondary and fuel battery

Containers for energy including battery require function to release internal pressures. In fact, the function is very sophisticated, as it is required to release pressures whenever internal pressures exceed a certain extent, while serving as lid for other times. This function is enabled by "Micro processing technology." The relief valve based on this technology was applied first to rechargeable secondary battery.

Battery technology including fuel battery has been dramatically evolving, and the relief valve is becoming increasingly important. We are determined to play a major role in promoting environmental technology by making the most of our experience and core technology.

ASAHI FR R&D Co.,Ltd.

- Company Name

ASAHI FR R&D Co.,Ltd. - Established

- April, 1987

- Location

- 2-7-2 Dote-cho, Omiya-ku, Saitama-shi, Saitama 330-0801, Japan

- Representative

- Yoichiro

Watanabe - Businesses

- Developing unique technologies that support ASAHI RUBBER INC.

1.Mission / Objective of the Laboratory

Our objective is to be a development division which helps ASAHI RUBBER INC. prosper by replicating in the current age the traditions that are the technological development and highly profitable structure of its early years. Specifically, through developing new materials and improving existing materials in response to changing needs, we aim to:

1.Build up the foundation for sales prices,

2.Generate the source for profits, and

3.Develop unique materials required by society.

2.For achievement of our objectives

1)Human Resources

- Grow as people aware of social responsibility and with a sense of ethics

- Develop human resources who can independently identify and solve issues

2)Research & Development

- Conduct challenging research through monitoring market trends

- Fully recognize the strength of our own company

- Focus on strategic initiatives

- Extensively analyze principles to explore opportunities for volume production from diverse angles

- Intensively study elemental technology for the upcoming five years starting from 2009, with more focus on elemental technology rather than product development

3.Elemental technologies handled by ASAHI FR R&D Co.,Ltd.

Surface modification (attachment), material denaturalization (composition), silicone technology, and research into potential technology (during the period from 2009 to 2010, oxynitride fluorescent body is being researched.)

4.Reference

Explanation on the concept of elemental technologies

1)What are elemental technologies?

These are regarded as the technological pillar supporting Asahi Rubber Group. They are the base for universal technologies, which include:

a. Color match & light control technology,

b. Material denaturalization (composition),

c. Surface modification (attachment),

d .Silicone application technology,

e. Die design, and

f. Processing technology related to these fields.

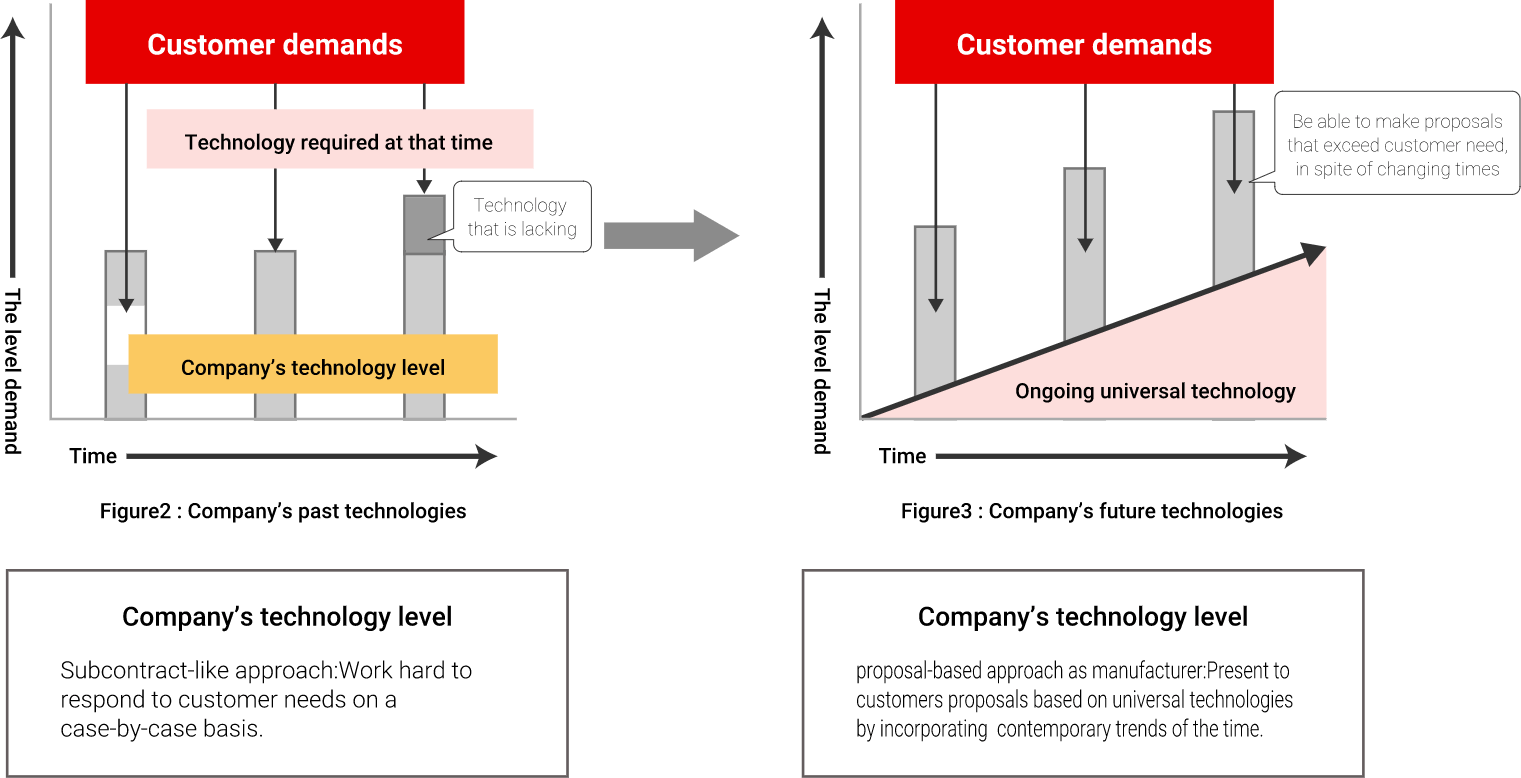

2)The necessity of universal technologies

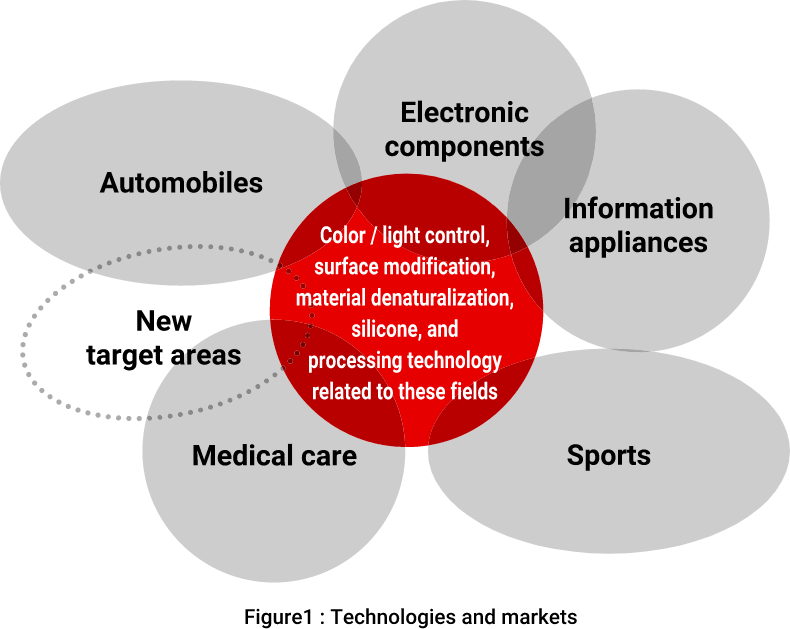

As it is shown in Figure 1, it is essential to differentiate the company by clearly defining our added value in order to be well recognized in the market.

As manufacturer, we are committed to contributing to the improvement of society through the cycle ranging from generating ideas and manufacturing products to marketing them. In order to manufacture products with distinctive advantages, our continuous efforts to research elemental technologies, which are core technologies for us, are the most important. Enhancing our elemental technologies, we are expanding our technological fields and universally applying them to new products.

3)The importance of intensively researching elemental technologies on a constant basis

As the environment changes with the times, customer needs are also constantly changing. In addition, competitors are promoting their initiatives to differentiate themselves by using creative ideas, while there is also a threat of new entrants to our market from different industries. In such times, the added value that will always gain support from customers is found in the reliability and uniqueness of our elemental technologies.

Figure 2 demonstrates the situation where we can only supply stopgap products incompatible with the current age and environment as a result of not intensively researching elemental technologies and blindly pursuing unfamiliar technologies. In this situation, we disperse our resources and fail to adequately explore elemental technologies.

Figure 3 demonstrates the situation where we can offer products of customer choice through our continuous efforts to intensively research elemental technologies, thus solidifying the business foundation continuously.