What are transparent resins with excellent characteristics and expanding applications?

What is transparent resin?

Transparent resin is used in various fields such as plastic parts for industrial products and headlight covers for automobiles and so on.

However, with recent technological innovations, high-performance resins are being developed.

In this section characteristic of the main types of transparent resins will be described. We will focus on what kind of transparent resin materials are required in the future.

What is the material of transparent resin?

There are a thousand different types of transparent resins.

Some are hard and fragile, while others are soft and break resistant.

It is important to choose the most suitable material because of the different manufacturing methods

and intended use.

What is characteristics of transparent resin?

In this section characteristic of the main types of transparent resins will be described.

Compared with conventional inorganic glass, it is more advantageous in various aspects.

High transparency

Characteristic of transparent resin is he high transparency. When light hits an object, it is reflected by the surface and absorbed by the object even if it penetrates inside. Some light spread out and exits from the back. Light coming out from the back is called “transmitted light”, therefore the higher the ratio, the better the transparency.

Generally, the transmittance of inorganic glasses is about 90%. However, transparent resin with a value of 90% or more is also present.

Light weight and shock-resistant

Compared with inorganic glass, it is light and resistant to impact.

In addition to its high transparency, it is resistant to impact and abrasion, and has the advantage of little deformation caused by water absorption or heat. Polystyrene and PET, which are inexpensive,

are not expected to have impact resistance. Transparent resins, on the other hand, have impact resistance

and are used as films, food containers and packaging materials.

Deterioration resistance

Resistance to climate changes is called “weatherability.” However, for transparent resin, a large amount of weather-resistant material is advantage.

Transparent resin is used outdoors in many cases, such as automobile headlamp covers, lenses, and decorative signs, and is highly resistant to the deterioration of UV rays, temperature changes, and oxidation-reactions.

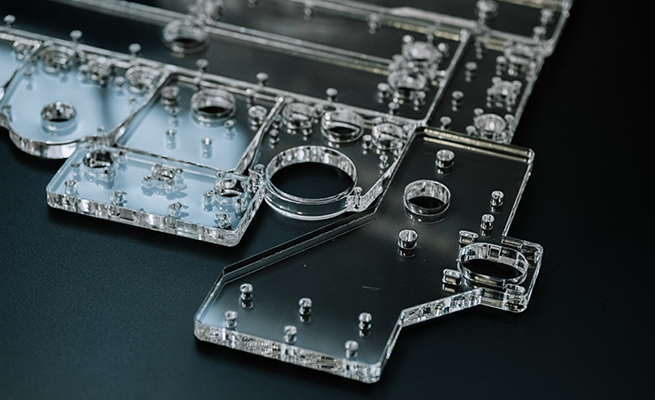

Easy to mold and versatile

Transparent resin’s features are easy to mold.

It is compatible with most of the basic molding methods for plastics, such as injection, extrusion,

vacuum and blow.

Therefore, conventional inorganic glass can be molded and processed into various shapes

that have been difficult.

What is the main type of transparent resin?

Plastic lens has tansparent

Let us explain about five types used in industrial products, etc.

The highest permeability of transparent resin is found in acrylics.

PMMA (acrylic-resin)

It is also used in large tanks in aquariums. It is durable enough to withstand high water pressure and has excellent shock resistance.

Compared with inorganic glass, it is light and resistant to impact.

PC (polycarbonate)

Although it is inferior to inorganic glass in permeability, it is 200 times more resistant to impact than acrylic resin and is used as a ballistic shield.

It is also highly resistant to heat and cold, and can be used in an environment of-100 to 130°C.

It is also highly acid-resistant, so it is suitable mainly for outdoor environments.

On the other hand, it is not very strong against harsh alkalis, and application of alkaline detergents or surfactants can cause cracking and deformation.

Applications include glasses, optical fibers, and camera lenses for smartphones, which are often used in products that are in close contact with our lives.

PS (polystyrene)

Polystyrene is a resin made from raw materials such as crude oil and naphtha. It has permeability comparable to inorganic glass and is used as a variety of materials.

It is widely used as a transparent material in CD cases, liquid crystal diffusers, packaging materials, etc., and is inexpensive and suitable for mass-production.

It has the advantage of being very light and easy to handle.

On the other hand, the disadvantage is that it is weak in heat and low in impact resistance.

In addition, it has the property of being soluble in oil and chemicals, so the application of this product

is quite limited.

AS resin

This material has permeability comparable to that of inorganic glass and improved heat and chemical resistance, which is a drawback of polystyrene.

They are also used as engineering plastics with enhanced impact resistance in combination with glass fiber, and are attracting attention as basic components that require safety.

However, it is not highly resistant to weathering, and it deteriorates when exposed to direct sunlight

for a long time, resulting in a disadvantage that it is easily burned.

Silicone resin

Silicone is produced using silicite and organic compounds with repeated chemical reactions.

It’s a material with a characteristic that is so good as to be called “magic sand.”

It is extremely durable and weather resistance, has no change in physical properties even at-70°C to 150°C.

Its excellent impact resistance and permeability are similar to those of acrylic resins.

They are attracting attention as materials that can be turned into glasses and acrylics. So they are used

as optical components and as household products such as interior goggles and accessories.

Silicone is hardened by mixing a hardener.

By adding a small amount of flame retardant in the manufacturing process, self-extinguishing properties can be gotten.

Transparent resin is used in a variety of applications.

In addition to packaging materials and electronic components, we are attracting attention regardless of the field thanks to industrial technological innovations.

Transparent resin as an optical material

These materials are now being replaced from glass by technological innovations.

Let’s take a look at transparent resin as a remarkable optical material.

Plastic lenses

For optical lenses, there seems to be an advantage in acrylic resins, which are highly permeable

and impact resistant.

In addition, since there is almost no distortion during molding, it can be said that the change in the refractive index is the smallest.

However, since acrylic has a slightly higher water absorption, the refractive index may increase due to changes in the humidity environment.

This is a bottleneck for high-precision applications.

This point seems to be solved by the development of alicyclic polyolefin resin with low hygroscopicity, etc.

Although acrylic resin is highly permeable, it has the disadvantage of easily absorbing wavelengths in the near-IR region.

Although improvements can be made by changing the molecular structure, there will be disadvantages such as higher costs.

Regarding display

AS resin and ABS resin are used for display sheets and so on thanks to their excellent durability, although their permeability is not so high.

It also has flexibility, so it is used as a packaging sheet.

The advantage of this material is that it is lightweight and easy to form, making it very inexpensive.

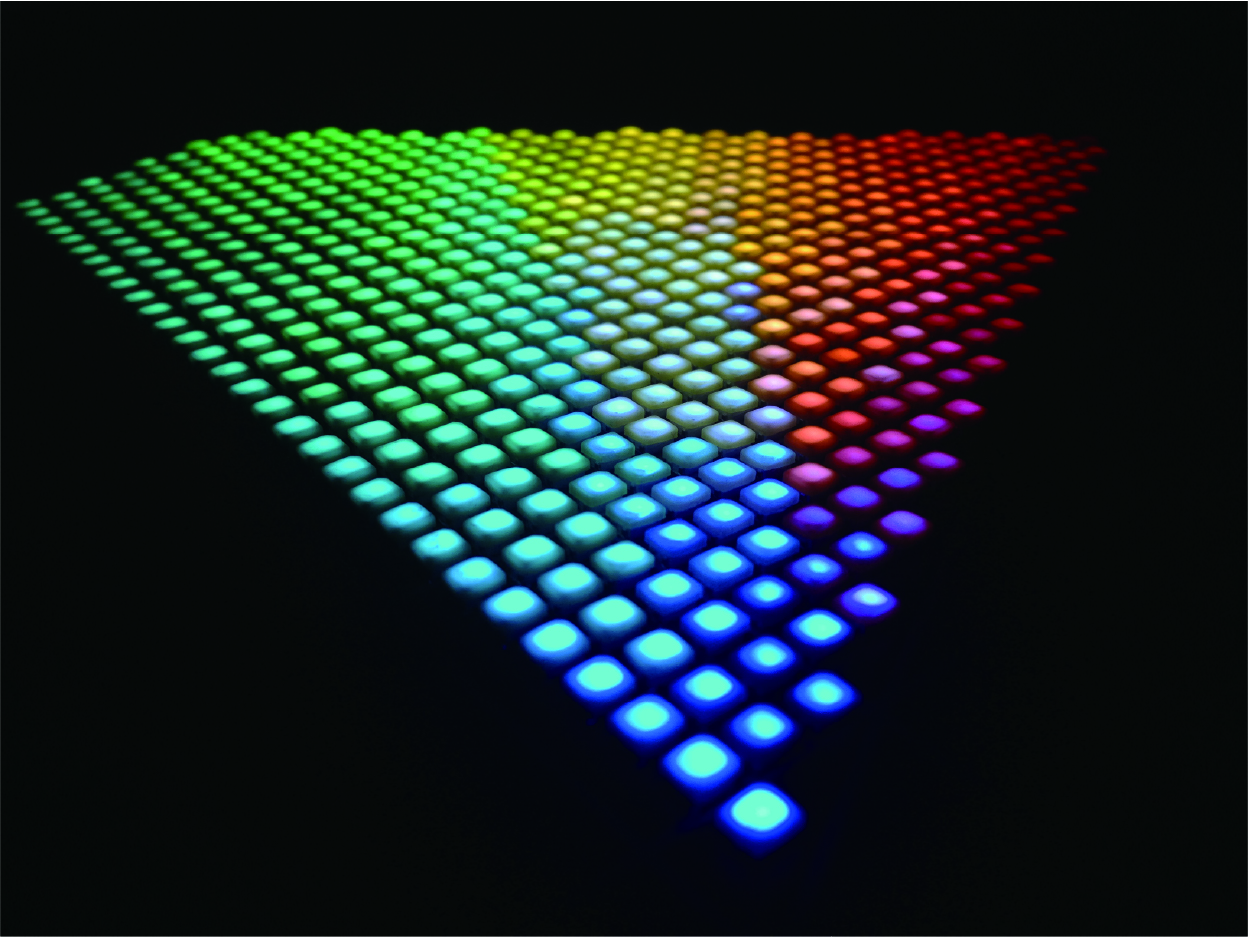

Materials for LED module

Acrylic and polycarbonate are commonly used as transparent resin for illumination parts, but silicone is attracting attention as the third material.

Liquid silicone allows for smooth resin flow during molding and even fills thinner parts and small spaces evenly.

In addition, it can be said that optical design using such characteristics is also easy.

Compared with hard transparent resin, it is rubber-like elasticity and can be designed to be very fine.

Because characteristics of the silicone makes it easy to mold (die-cut), it is also possible to be various shapes.

What is the issue of transparent resin?

Although transparent resins have the advantage of being widely used, each type of resin has its own disadvantages.

Acrylic resin, which is called “plastic queen” and has no major drawbacks, is said flammable and to be vulnerable to frictional.

Other transparent resin materials have some drawbacks, such as weak impact, poor heat resistance, and the possibility of degradation by UV light.

What is a transparent resin with resistance?

When we look at the properties, advantages, and disadvantages of the transparent resins listed above,

we find that silicone is the most resistant material.

The term “silicon” is often used, but silicon is simply silica stone as a raw material.

Only after repeated chemical reactions and commercialization can a material be called a silicone.

Compared to other transparent resins, silicone has no drawbacks and is not very expensive.

We believe that silicone can be regarded as a transparent resin material for the next generation.

Summary

ASA COLOR LENS can be applied in optical products. It offers design and price proposals that match the application of silicone materials.

It is compatible with inorganic glasses and special shapes that have not been achieved with hard transparent resin. It has high permeability of 95.4%, it transmits wavelength in the near IR region, an advantage over acrylics.

In terms of durability, it has great advantages in terms of UV resistance, impact resistance, heat resistance, and chemical resistance, and exhibits excellent characteristics under any circumstances.

Other articles

How to pick up reflective paint

How to pick up the most suitable paint for each application

Be applied in industrial fields.

Features and use of UV light