WHITE SILICONE INK for Ultraviolet applications

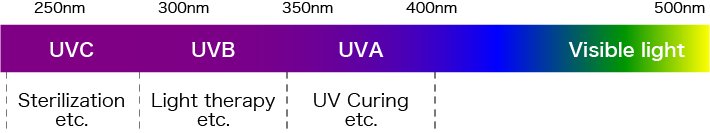

Introduction – Ultraviolet (UV) market –

The UV industry is growing in equipment business such as UV irradiators and in material business such as UV adhesives and inks. It is expected to expand its market to living space with various sterilization applications as well as to medical equipment. By utilizing its existing business infrastructure on optical products, ASAHI RUBBER continues to propose innovative products to the UV industry.

Product selection

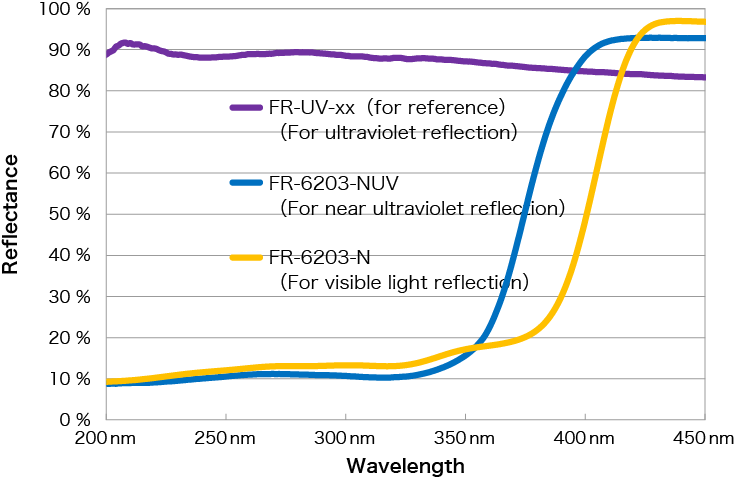

White silicone inks for UV are available for near-ultraviolet (NUV) and deep-ultra (DUV).

| DUV | NUV | |

|---|---|---|

| 250~365nm | 385~405nm | |

| Hard type | FR-UV-xx / PR-UV-xx (Under development) | FR-6203-N |

| Soft type | SWR-UV-xx (Under development) | SWR-PK-03-NUV |

Resistance against ultraviolet irradiation

White silicone ink for UV has extremely strong resistance to UV and at the same time protects the object to be coated from UV light, so it improves UV resistance by painting in places where deterioration by UV light is a concern.

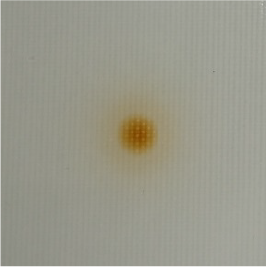

PCB(FR-4)(with“no ink coated”)

PCB(FR-4) with SWR-PK-03-NUV coated

Compared with “no ink coated”, neither discoloration nor visual/appearance deterioration on the test piece surface are observed.