Products for wind turbine blades

【Developing product】

In the field of wind power generation-related products, we are developing and evaluating a variety of value-added products that can be mounted on wind turbine blades not only on land but also offshore, such as plasma airflow control electrodes using Asahi Rubber’s proprietary material technologies and molecular adhesion and bonding technologies, divertor strips, protective sheets and shells, and we believe that these products will be useful to our customers.

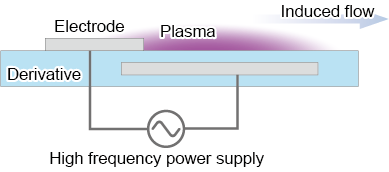

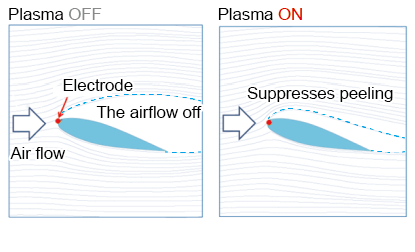

Plasma actuator

Airflow control electrodes to improve efficiency and life of wind turbine blades

(jointly developed with Hokutaku Co.,LTD, FREA(Fukushima Renewable Energy Institute) of AIST)

Plasma discharge is generated by applying a high voltage between the electrodes, and air flow is induced along the blade surface to suppress airflow separation.

Divertor strip

Protects blades from severe lightning strikes in Japan

(jointly developed with Hokutaku Co.,LTD, Moriya Cutlery Laboratory, Ltd., Chubu University, Shimane Institute for Industrial Technology)

The specially developed metal chips are bonded and sealed to highly weatherproof silicone rubber using our proprietary “Molecular Adhesion and Bonding Technology” to create a product that can withstand harsh environments.

- Directs lightning strikes to receptors, reducing damage from direct hits

- Withstands multiple lightning strikes and reduces maintenance

- Flexible construction makes it easy to fit and construct on curved surfaces of blades

- For lightning protection on building walls, communications equipment, aircraft materials, etc.

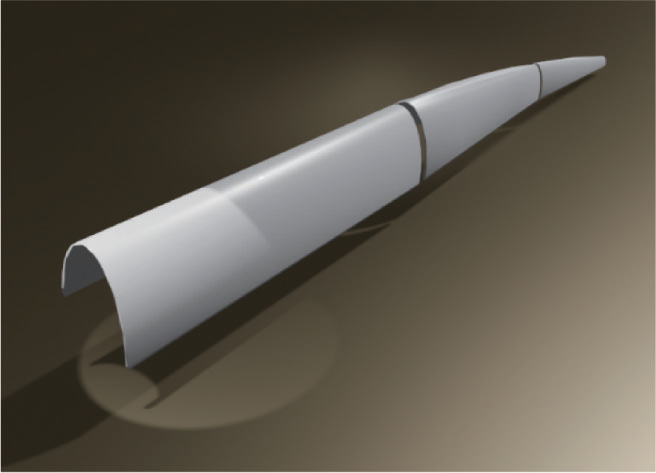

Protective sheeting and shells

Long-term protection of the leading edge of blades rotating at high speeds

(Jointly developed with Hokutaku Co.,LTD)

Based on industrial silicone rubber, finished into protective products with excellent durability and ease of use.

The elasticity that remains unchanged in cryogenic and hot weather protects the blade.

*Conform to wind form urbine painting standards (ISO/TS 19392-1)

Characteristic

Use highly durable materials

- Highly weather resistant and UV resistant

- Maintains physical properties over a wide temperature range (-50°C to +200°C)

- High water resistance and resistance to water absorption (= less embrittlement and stability over time)

- High water repellency

- High electrical insulation

Top coat possible

- Higher durability by combining with special paint

Easy Construction

- Easy handling with split type

- Double-sided tape on back side

Enduarance for erosion

- Unique test confirms excellent durability

- Using materials that have been operated for 3 years on actual onshore wind turbines

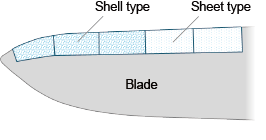

Specifications

| Sheet type | Shell type | |

|---|---|---|

| Width | 40~200mm | Create according to the curved surface of the blade |

| Length | 500~1,000mm | |

| Thickness | 0.5~2mm Including adhesive layer |

|

| Color | White, gray. Others are available | |